difference between autoclave and out of autoclave|Introduction to Out : agency Pressure Cooker vs Autoclave: Differences in the Steam. You might look at the difference between the pressure cooker and the autoclave as a difference in design too. Pressure cookers, in comparison, will use a large saucepan that cooks food quickly. The boiling water builds steam and pressure in the cooker. $299.99

{plog:ftitle_list}

Esplora la nostra selezione di casette in legno impregnato in autoclave, trattate per resistere agli agenti atmosferici e garantire la massima durata. - Casetta MiaDifferenze tra casette in legno naturale e impregnato in autoclave. In fase di acquisto di una casetta in legno, bisogna quindi interrogarsi sulla possibilità di scegliere un modello in legno .

Out of autoclave composite manufacturing

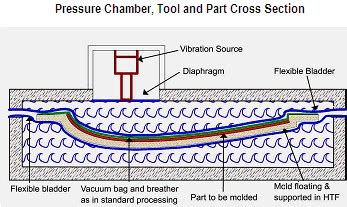

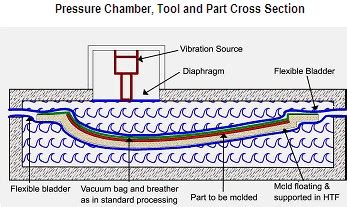

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum.

%PDF-1.7 %âãÏÓ 4276 0 obj > endobj 4288 0 obj >/Encrypt 4277 0 R/Filter/FlateDecode/ID[1564B57341670E45ABF57AA58477559A>]/Index[4276 29]/Info 4275 0 R/Length 79 . Pressure Cooker vs Autoclave: Differences in the Steam. You might look at the difference between the pressure cooker and the autoclave as a difference in design too. Pressure cookers, in comparison, will use a large saucepan that cooks food quickly. The boiling water builds steam and pressure in the cooker.Difference between Autoclave and Dry Heat Sterilizer. Sterilization by steam is carried out by a specialized pressure-induced chamber called an autoclave that uses high-pressure steam to sterilize equipment and supplies. It is one of the most common and the oldest methods for sterilization of instruments and materials, mostly used in dental .

ce iso centrifugal water pump spare parts

Out of autoclave composite manufacturi

A study from the British Journal of Dentistry showed that after a single day’s use, the level of gram-negative bacteria, as well as endotoxins, reached unacceptable levels in benchtop autoclave water reservoirs. 2 Thus, not only is ensuring proper operation of an autoclave critical, but regular, daily maintenance is required to ensure patient safety.

The World Health Organization recommends autoclave cycles run between 121 and 124 C for 15 minutes at about 30 PSI. This should be enough time to kill any microorganism. Autoclaves are common place in most labs and are an obvious choice for many applications. Drawbacks include overhead costs for the autoclave, as well as utility costs to run . Regardless of autoclave class and type, all sterilizers operate using high-temperature, saturated steam under pressure, usually between 1.1 and 2.1. bar. The temperature can range between 121 and 134 degrees Celsius and helps eliminate even heat-resistant bacteria. Comparing and ranking autoclave types: N, S, and B classesAn autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure/temperature. Autoclaves are used in medical applications to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Because it is an autoclave built for maximum program flexibility, a research and development retort from Priorclave can do all the usual things any autoclave can (like sterilizing glassware and lab tools, or preparing growth media for culturing spores or fungus). But it can also simulate the full range of retort sterilization environments, but .

A horizontal autoclave will have a door which opens outwards towards you. At Astell we refer to these as ‘front loading autoclaves’. These are available in sizes starting at 33 litres chamber capacity (in our Benchtop range), going up to 344 litres for the largest of the ‘Swiftlock’ range.Astell SQUARE range autoclaves also have a horizontal chamber, all with an integral .

The choice between a pressure cooker and an autoclave depends on the specific application and requirements. Yes, pressure cookers can be used for home canning, but it is essential to follow the manufacturer’s instructions carefully and ensure the appropriate pressure and duration are maintained. Autoclave and out-of-autoclave (OOA) processing refer to the manufacture of composite parts from fibre reinforcements pre-impregnated with a thermoset resin (prepreg), using either a pressurised autoclave vessel or a vacuum bag-only system. . The main difference between the two approaches is that the autoclave uses pressurised gases that . What is the difference between a Class B and a Class N autoclave? The primary difference between Class B and Class N autoclaves is how they remove air from the chamber prior to sterilization. Class B autoclaves utilize a vacuum pump to completely remove air from the chamber, which enables steam to better penetrate the load.

Know the difference between autoclaving and sterilization, benefits of steam sterilization, what is gamma or e-beam radiation, why sterilization is necessary for medical devices, and cost of autoclaves. . There was a significant association between the type of autoclave and the failure rate. It is not clear why. However, it is possible that .Comparison of Autoclave and Out-of-Autoclave Composites* James K. Sutter1, W. Scott Kenner2, Larry Pelham3, Sandi G. Miller1, . diffusivity difference between samples. Typical instrument settings were: 96 kJ flash power, providing a 5-10 oC, frequency 15.00 Hz, .Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material.Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. [1] OOA curing achieves the desired .

centrifugal fan 190mm

• Dissolved gases that come out of the solution. • Reduction of the head space due to the thermal expansion of the liquid. P. v . the difference in pressure between the chamber and the container itself. 15. Superheated water autoclave. process phases. Time. . autoclave framework, but also the circulating water .

what is an autoclave sterilization machine|difference between autoclave and sterilizer : distributor An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure .

One of these things to take into consideration is if you want a manual autoclave or an automatic autoclave. Both have their differences that should be considered when purchasing. So in this article, we’ll help compare and contrast manuals versus automatics and help you make a more informed decision when buying your autoclave.

Autoclave size is also a key factor that needs to be taken into account: the right choice here depends on the amount of waste your facility needs to be treated each day, as well as the amount of available space you have. Large steam sterilizers. The capacity of these types of autoclaves usually ranges between 110 to 880 liters. One major difference between an autoclave and a dry heat sterilizer is the mechanism of action. The autoclave uses a combination of heat, pressure, and steam to sterilize equipment and medical devices, while the dry heat sterilizer uses only high temperatures. The autoclave is ideal for materials that can withstand heat and pressure, while the . It is important that the validation of the autoclave is carried out with calibrated measuring equipmentso that pressure and temperature are reliable values. Re-commissioning. Re-commissioning corresponds to autoclave commissioning in terms of procedure and differs only in terms of the interval at which it is carried out. Gravity Autoclave Cycle . Gravity autoclaving, also known as gravity displacement autoclaving, is the most basic form of autoclaving. The process of gravity autoclaving involves replacing all ambient air in the autoclave chamber and forcing it out of the exhaust valve. This is done so that the steam can sterilise the objects inside the autoclave.

I dont think there is a difference between the two in terms of sterility. Autoclaving can cause some reagents in the media to degrade. The high heat can also cause precipitation of salts which is why some recipes tell you to sterile filter parts and then add . Water at high pressure level is used in moist heat sterilization. Autoclave is the instrument in which this process is carried out. The temperature of the st.

Consolidated Sterilizer Systems What is the difference between a horizontal and vertical autoclave?. The most reliable and easy-to-use steam autoclaves in the world. We're Attending Future Labs 2024! . While a horizontal autoclave features a chamber that’s horizontally oriented and accessed via the front of the unit, a vertical autoclave .The Difference Between a Sterilizer and an Autoclave . While many say that sterilizers and autoclaves are synonymous, they are more like a tree-sterilizers are the trunk that autoclaves branch out from. A sterilizer is a general term for any equipment that can sterilize. An autoclave sterilizer is a specific device that sterilizes equipment.

Introduction to Out

Very Cool Nostalgic 1950's Original Salmon Pink Wilmot Castle Autoclave Sterilizer on Original One door lighted stand with inside tray. Sterilizer does come on and appears to be in working condition. Price includes Sterilizer and .Castle Autoclave Castle M/C 3522 Gravity Laboratory Sterilizer with steam generator is designed to steam-sterilize hospital and laboratory supplies. Processing temperature range from 100 .

difference between autoclave and out of autoclave|Introduction to Out